YAHOO AUTOS

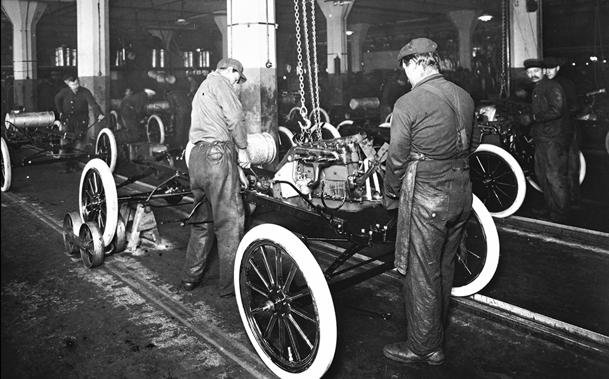

While Henry Ford wasn't caught off-guard by the success of the Model T in 1908, the demand soon put a strain on his company. Despite opening a new plant in the Detroit enclave of Highland Park, assembly still required thousands of men shuffling parts around a sprawling factory.

It wasn't just Ford; other automakers had yet to find a method that could produce vehicles efficiently at high volume. Under the oversight of engineer Charles Sorenson, Ford experimented with scores of changes throughout the factory for years — pushing the chassis between workers, or sliding parts down ramps.

The breakthrough came in April 1913, when the engineers overseeing the flywheel magneto assembly divided the work into 29 separate steps, with one man per step, moving the part among them.

On this day 101 years ago, Ford rigged its first moving final assembly line at Highland Park — pulling Model T chassis on ropes down a 150-foot track, past 140 workers along the sides.

The time for assembling a single Model T fell from 12 1/2 man-hours to five hours 50 minutes — lowering Ford's costs, boosting its output far beyond its competitors and sparking the modern era of manufacturing.

The efficient tedium of those jobs would later lead to Ford's $5-a-day wage; the push for standardizing tasks in everyday life and the changes it wrought would soon be labeled "Fordism."

No comments:

Post a Comment